Surface processes

Surface finishing

Surface finishing of metal semi-finished products is a crucial process in the manufacturing industry. This is a set of operations that are carried out on the surface of the raw metal to improve its aesthetic, functional and strength characteristics. This process is crucial to ensure that finished products are of high quality and meet the required standards.

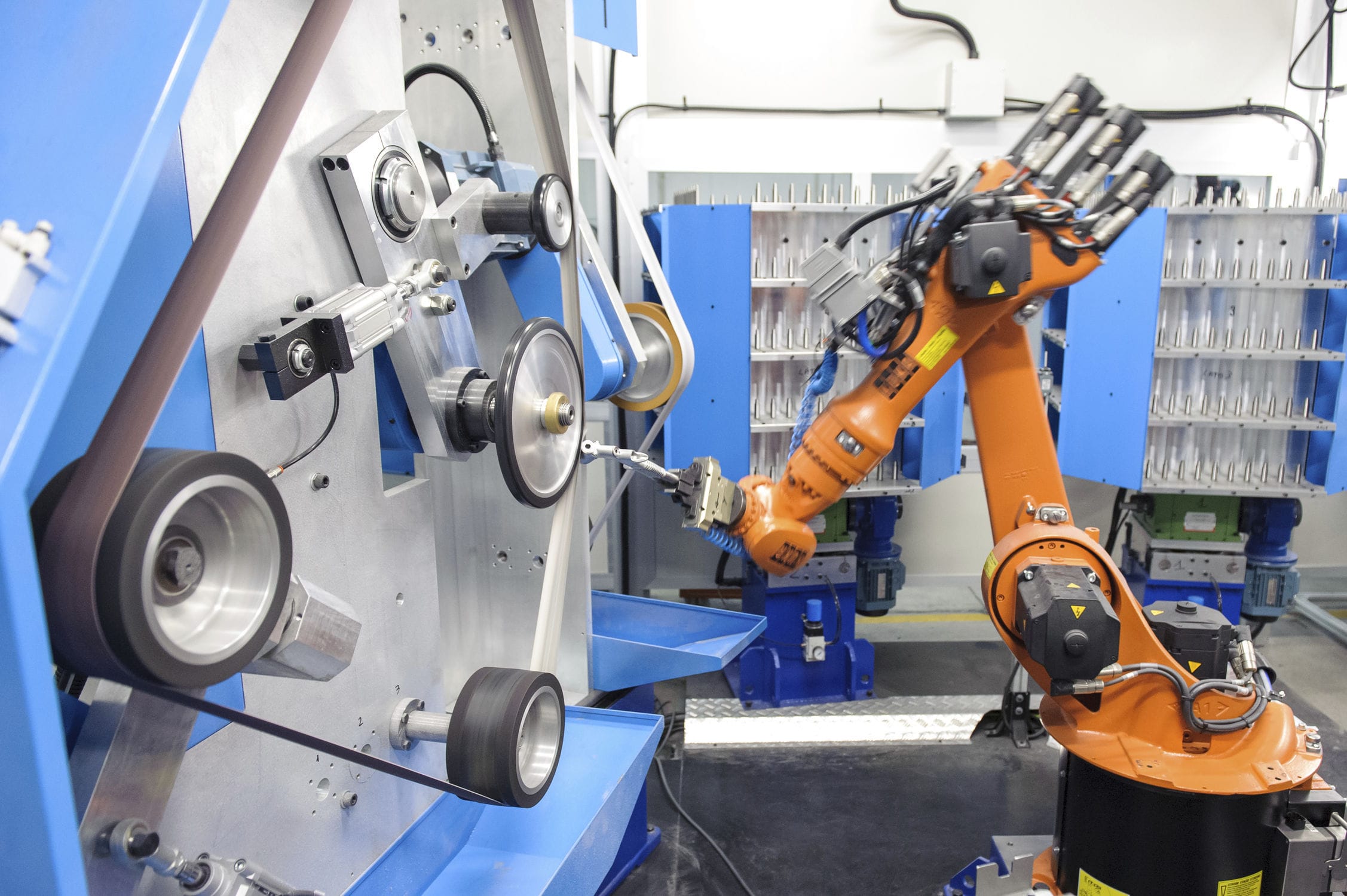

Robotic and manual deburring

Il processo di sbavatura dei metalli consente di eliminare in modo accurato tutte le imperfezioni risultanti dalle fasi iniziali di lavorazione, come ad esempio taglio e fusione. Si tratta della fase primaria che coinvolge tutte le superfici metalliche prima di procedere con ulteriori operazioni di lavorazione. Questo procedimento riveste un’importanza fondamentale nell’ambito della produzione di componenti di eccellente qualità, soprattutto nel settore dell’ingegneria e della meccanica. Tale settore richiede l’impiego di operatori altamente specializzati e l’utilizzo di strumentazioni altamente precise, affidabili ed efficienti, conferendo così un ruolo di primo piano a questo processo.

10 robotic islands from 30 to 165 kg

Sandblasting

Blanket sandblasting is an automated process for casting, in which the components are arranged on an abrasive rubbery carpet that makes them rotate while being hit by the abrasive jets.

Tunnel blasting involves the use of a tunnel to treat bulky components, with direct abrasive jets from different directions for uniform cleaning.

Cluster sandblasting uses small abrasive particles projected strongly on the components to remove impurities and improve the adhesion of materials.

Available in blanket, tunnel and cluster

Grinding

Grinding is a process of machining metal surfaces or other materials, in which an abrasive is used, often in the form of grinding wheels or abrasive belts. This process aims to remove excess material, finish the surface and create a smooth and uniform finish. Grinding is often used to improve the dimensional accuracy, flatness and roughness of component surfaces. We have a dedicated line of 10 robotic islands with capacity from 30 to 165 kg

Automatic cutting

- manual saws: designed for small and medium-sized sawing needs from 0 to 45°

- automatic sawing machines: equipped with benches (table sizes up to 1200X1700) with automatic feed, guarantee excellent finish, precision in lengths

- Robotic islands: for cutting large castings, the cutting takes place inside cabins where the robot operates in total safety, the same allows us to make cuts up to 360°

- 3 Robotic cutting islands with load capacities from 165 kg up to 300 kg